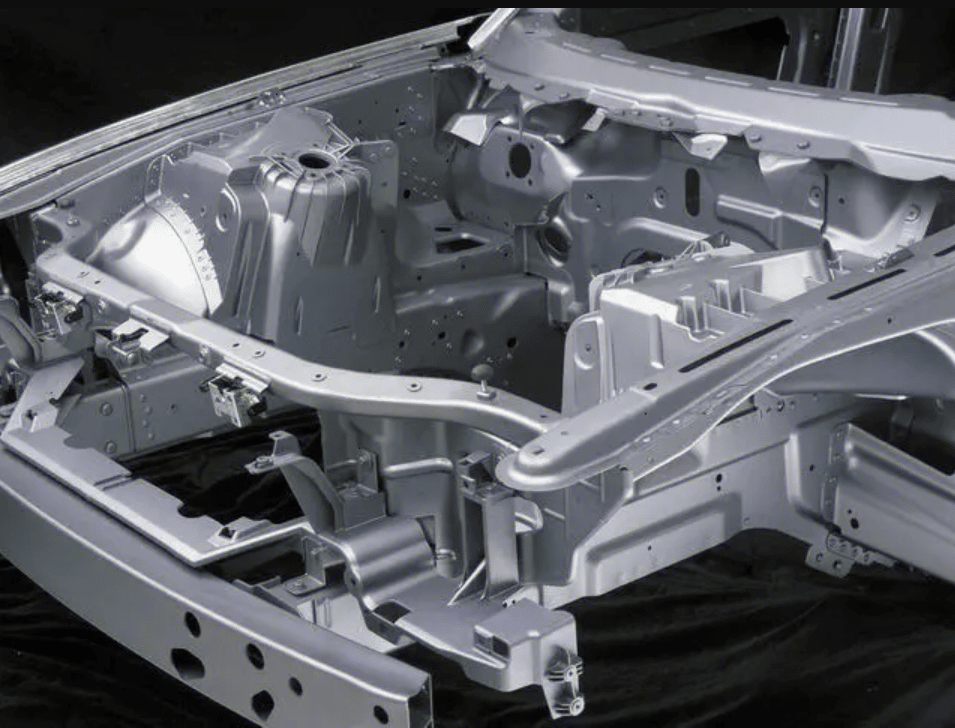

Automobile sheet metal parts generally refer to the metal shell of the automobile, usually made of steel plates. On the basis of ensuring a certain strength, reducing the weight as much as possible is the basic requirement. In addition to protection and beautification, automobile sheet metal parts are also the main carrier for automobiles to withstand air resistance.

Sheet metal for car repair is a technical means of automobile repair. In this respect, automobile sheet metal is equal to automobile sheet metal repair, that is to say, the body needs to be repaired after a collision, that is, all other work except for body anti-corrosion and decorative spraying. Such as body damage analysis, body measurement, body sheet metal forming, stretch correction, stress relief welding, body accessories assembly adjustment, etc.

Sheet metal for car repair is a processing method for automobile maintenance, also called cold processing. To put it bluntly, if the appearance of the body is damaged or deformed, the process of sheet metal is required. Automobile collision repair has developed from the initial “smashing, drawing and welding repair” to the secondary manufacturing and assembly of the body. The repair of a crashed vehicle is no longer a simple car sheet metal beating, and the quality of the repair cannot simply rely on the appearance and cracks of the vehicle with the naked eye. Maintenance personnel should not only understand the technical parameters and external dimensions of the car body, but also master the material properties of the car body, the transfer of stress characteristics, the deformation trend and stress points of the car body, and the production process of the car body such as welding process. On the basis of mastering these knowledge, maintenance personnel should also use advanced measurement tools and accurate three-dimensional measurement of the body to judge the direct or indirect damage and deformation of the body and the hidden dangers caused by the deformation of the body, and formulate a complete body repair plan. Then, with the help of correct maintenance technology and accurate weighing of the three-dimensional dimensional data of each key point, the key points of the car body will be restored to their original positions, and the damaged car body will be restored to the factory state.

The key processes of Sheet metal for car repair can roughly include:

- Body disassembly

- Body Correction

- Body repair

What is a Sheet metal for car repair program

The work of the sheet metal depends on the condition of the car repair. Most of them started removing the sheet metal parts where the damage was. Next, sand off the original paint in the damaged area. If the sheet metal part is dented, use a tool to flatten the sheet metal part, and finally turn off the fire.

First you need to sand the transitional surface between the damaged area and the car paint, then apply primer to the damaged area, scrape putty, clean and remove oil stains, then spray the intermediate primer, dry and sand. A professional painter should do a good job of mixing, spraying and polishing.