Why On-machine Inspection is Important for CNC Machining

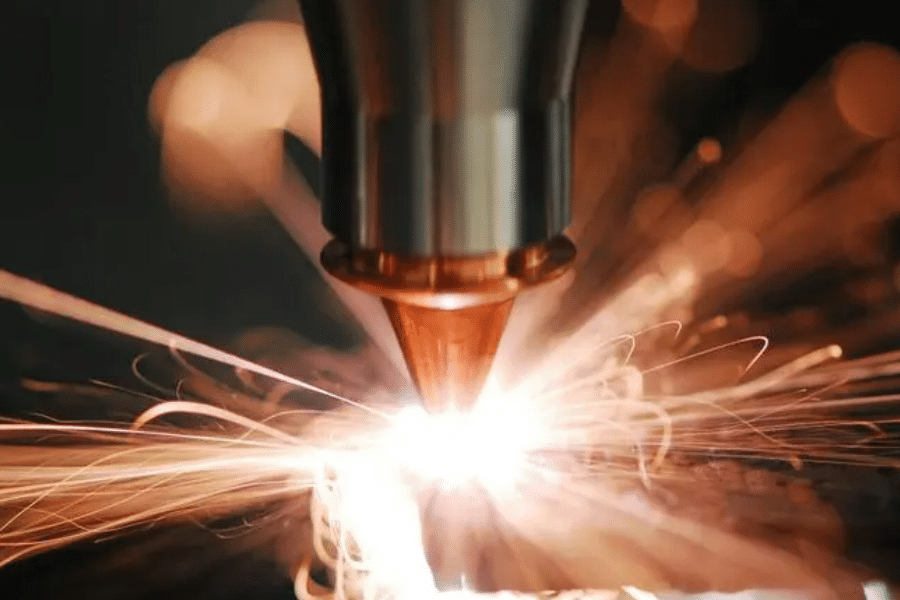

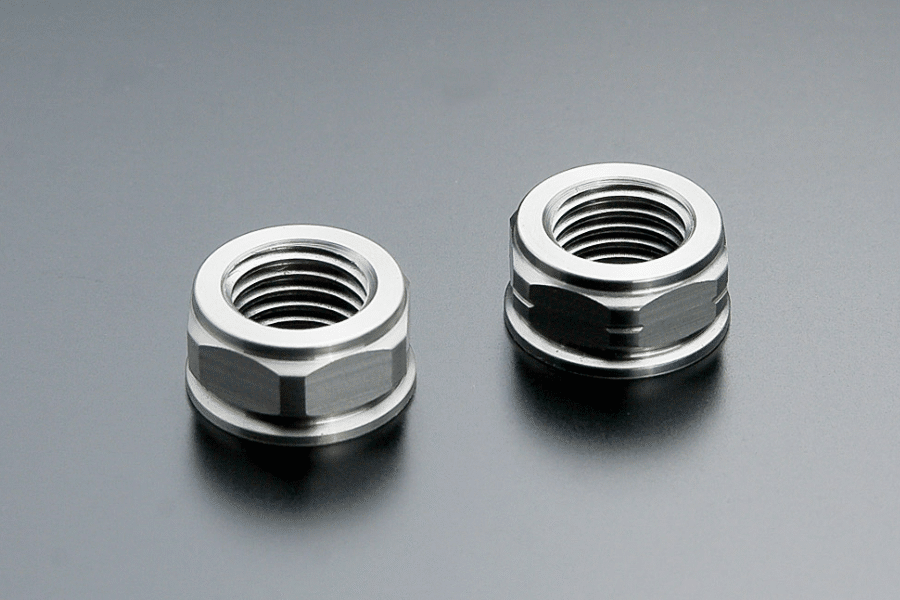

What is On-machine Inspection On-machine inspection refers to the process of inspecting and evaluating products or components directly on the manufacturing machine itself. Instead of taking the items off the production line and moving them to a separate inspection area, inspections are conducted using sensors, cameras, and other technologies integrated into the machine. This inspection […]

Why On-machine Inspection is Important for CNC Machining Read More »