CNC machining is a widely used manufacturing process for producing molds and dies, which are crucial components in various industries, including automotive, aerospace, electronics, and consumer goods. China has established itself as a prominent player in the global manufacturing market, including mold and die production, due to its cost-effective capabilities and advanced technology.

When considering CNC machining in China for mold and die production , there are several important factors to keep in mind:

- Supplier Selection: Choose a reputable CNC machining supplier that specializes in mold and die production. Look for companies with a proven track record in producing high-quality molds and dies for your specific industry.

- Experience and Expertise: Check the supplier’s experience and expertise in producing molds and dies that match your design requirements. They should be familiar with the intricacies of mold and die design and manufacturing processes.

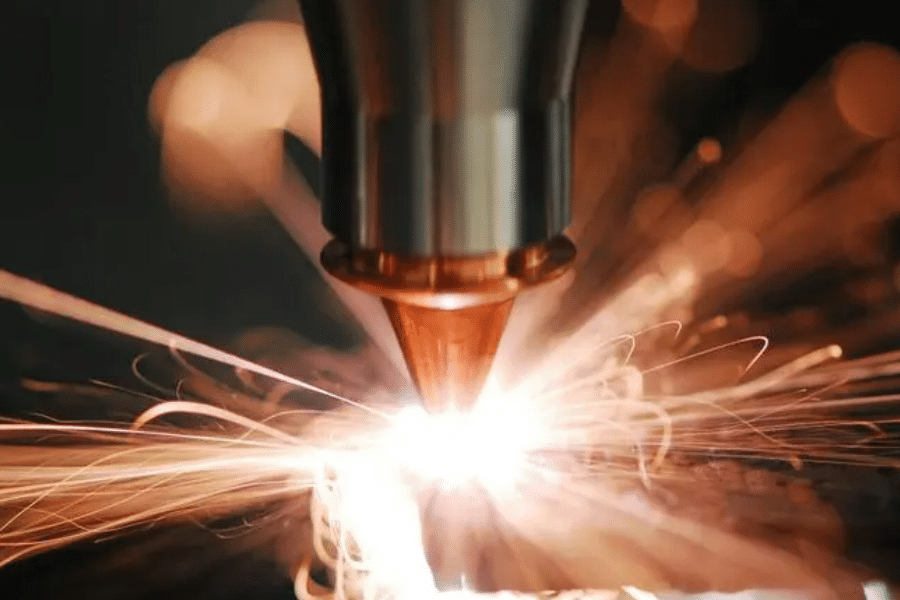

- Advanced Technology: Evaluate the CNC machining equipment and technology used by the supplier. Advanced machinery can contribute to higher precision, faster production, and better quality.

- Materials: Different molds and dies require specific materials based on factors such as durability, thermal conductivity, and wear resistance. Ensure that the supplier can work with the materials that meet your requirements.

- Quality Control: Implement a robust quality control process to ensure that the produced molds and dies meet your specifications. This can include regular inspections, measurements, and testing.

- Tolerances and Accuracy: Molds and dies often require tight tolerances and high accuracy to ensure the quality of the final products they will produce. Make sure the supplier is capable of achieving the required tolerances.

- Communication: Effective communication is essential to ensure that your design specifications are accurately translated into the final products. Clear communication can help prevent misunderstandings and errors.

- Lead Times: Consider the lead times for mold and die production. Faster lead times might be necessary for time-sensitive projects or industries with rapidly changing product designs.

- Intellectual Property Protection: Protecting your intellectual property is crucial. Work with legal advisors and consider using non-disclosure agreements (NDAs) and other measures to safeguard your designs and proprietary information.

- Logistics and Shipping: Plan for shipping logistics and any potential delays that might occur during transportation. Choose a reliable freight forwarding partner if needed.

- Cost Considerations: While cost-effectiveness is often a factor in outsourcing to China, prioritize quality and reliability. Balancing cost with quality is essential to ensure the molds and dies meet your production needs.

- Relationship Building: Building a strong working relationship with your Chinese supplier can lead to smoother communication, better understanding of your needs, and potential long-term collaborations.

Before finalizing your decision, conduct thorough research, visit potential suppliers if possible, and consider seeking recommendations from industry peers. Working with experienced consultants or professionals who have expertise in mold and die production and international business can provide valuable insights and guidance throughout the process.