What is on-demand manufacturing

On-demand manufacturing, also known as custom manufacturing or manufacturing on-demand, is an approach to production that focuses on manufacturing products in response to specific customer orders or demands, rather than producing in bulk or maintaining large inventories. It involves producing goods as needed, typically in smaller quantities or even on a one-off basis. Here are some key aspects of on-demand manufacturing:

- Customization: On-demand manufacturing enables customization and personalization of products to meet individual customer requirements. It allows for tailoring products to specific designs, sizes, colors, or features based on customer preferences.

- Rapid Production: On-demand manufacturing provides quick turnaround times, as production starts soon after receiving the customer’s order. This allows for faster delivery and reduced lead times compared to traditional manufacturing methods.

- Flexible Production: On-demand manufacturing is adaptable to fluctuations in demand. It allows for scaling production up or down based on customer orders, market demand, or specific business needs.

- Reduced Inventory Costs: Since products are manufactured in response to customer orders, on-demand manufacturing helps reduce inventory holding costs. It eliminates the need to maintain large stockpiles of finished goods, raw materials, or components.

- Cost Efficiency: On-demand manufacturing can be cost-effective, particularly for low-volume or custom production. It eliminates the need for large upfront investments in inventory, machinery, or tooling. It also minimizes the risk of overproduction and potential waste.

- Digital Integration: On-demand manufacturing often leverages digital technologies, such as computer-aided design (CAD), digital prototyping, and 3D printing. These technologies enable efficient and agile production, allowing for faster design iterations and reduced setup times.

- Sustainability: On-demand manufacturing can contribute to sustainable practices by reducing waste and minimizing environmental impact. It promotes lean production principles, as goods are produced based on actual demand rather than speculative forecasts.

On-demand manufacturing has gained popularity due to its ability to offer customization, shorter lead times, cost efficiency, and flexibility in meeting customer demands. It is commonly used in industries such as apparel, footwear, consumer goods, 3D printing, and personalized products.

How does on-demand manufacturing work

On-demand manufacturing, also known as custom manufacturing or manufacturing on-demand, is a process that involves producing goods in response to specific customer orders or demands. Here’s a step-by-step explanation of how on-demand manufacturing works:

- Customer Order: The process begins when a customer places an order for a product. This can be done through various channels such as an e-commerce website, online marketplace, or direct communication with the manufacturer.

- Product Design and Customization: If the product allows for customization or personalization, the customer provides their desired specifications. This may include size, color, features, or design elements. Digital tools like configurators or product design software may be used to capture and validate the customer’s requirements.

- Manufacturing System Integration: The customer order is integrated into the manufacturer’s production system. This can involve connecting the e-commerce platform or order management system with the manufacturing software or ERP (Enterprise Resource Planning) system. The integration enables seamless communication and data transfer between order processing and production planning.

- Production Planning and Scheduling: Once the order is received, the manufacturer plans the production process. This involves determining the required materials, scheduling resources (such as machinery and labor), and optimizing the production sequence to meet the order’s delivery timeline.

- Material Procurement: If the product requires specific raw materials, the manufacturer procures them based on the order specifications. This can involve sourcing materials from suppliers or using existing inventory, depending on the availability and lead time requirements.

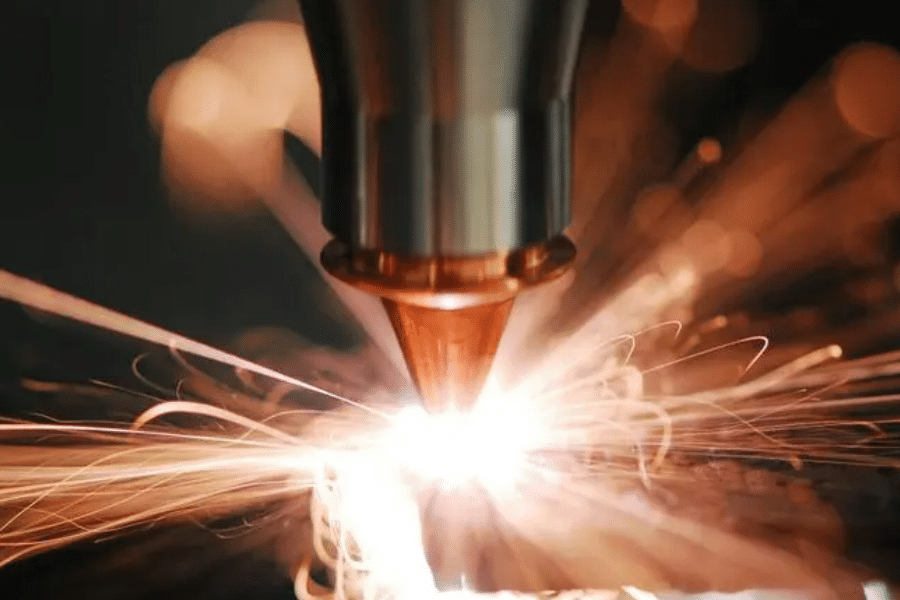

- Production Execution: The manufacturing process begins according to the order specifications. Depending on the product and manufacturing method, various processes may be involved, such as machining, 3D printing, assembly, or fabrication. The production floor personnel or automated systems carry out the necessary steps to create the product.

- Quality Control: Quality control measures are implemented throughout the manufacturing process. Inspections, testing, or sampling may be conducted to ensure that the product meets the specified requirements and quality standards. Any deviations or non-conformities are addressed and rectified before moving to the next step.

- Packaging and Shipping: Once the product is manufactured and passes quality control, it is appropriately packaged for shipment. This includes labeling, branding, and ensuring proper protection during transportation. The shipping method and logistics are determined based on the customer’s preferences and location.

- Delivery and Customer Satisfaction: The product is then delivered to the customer’s designated location. Tracking information may be provided to allow the customer to monitor the shipment. Upon delivery, the customer assesses the product and provides feedback on their satisfaction with the purchased item.

- Post-Sales Support: After-sales support may be provided to address any customer inquiries, issues, or additional service requirements. This can include warranty services, repairs, or replacements, depending on the product and customer needs.

The on-demand manufacturing process revolves around efficiently producing customized products based on specific customer orders, eliminating the need for mass production and excessive inventory. It leverages technology, integration, and agile production methods to deliver tailored products with shorter lead times and increased customer satisfaction.