Features of CNC machining:

- The degree of automation is high, and the production efficiency is very high. Except for blank clamping, all other processing operations can be completed by CNC machine tools. If combined with the automatic loading and unloading method, it is a basic part of the unmanned control factory. CNC machining reduces the labor of the operator, improves the labor conditions, and saves the processes and auxiliary operations such as marking, multiple clamping and positioning, and testing, and effectively improves the production efficiency.

- Adaptability to CNC machining objects. When changing the processing object, in addition to changing the tool and solving the blank clamping method, only reprogramming is required, and other complex adjustments are not required, which shortens the production preparation cycle.

- High machining accuracy, stable quality, machining dimensional accuracy between d0.005-0.01mm, not affected by the complexity of the parts, because most of the operations are automatically completed by the machine. Therefore, the size of batch parts is increased, and the precision control The position detection device is also used on the machine tool, which further improves the precision of precision CNC machining.

- CNC machining has two main features: one is that it can greatly improve the machining accuracy, including machining quality accuracy and machining time error accuracy; the second is the repeatability of machining quality, which can stabilize machining quality and maintain the quality of machined parts,say, CNC aluminum parts, cnc brass parts, cnc stainless steel parts.

When carrying out CNC machining, improvement operations should be carried out according to these characteristics of CNC machining to better improve machining efficiency and machining quality.

Mechanical parts processing technology refers to the process of changing the size or performance of machined parts through a mechanical device. According to the different processing methods, it can be divided into cutting processing and pressure processing.

The processing methods of mechanical parts mainly include: turning, pliers, milling, planing, inserting, grinding, drilling, boring, punching, sawing and other methods.

It can also include wire cutting, casting, forging, electro-corrosion, powder processing, electroplating, various heat treatments, and the like.

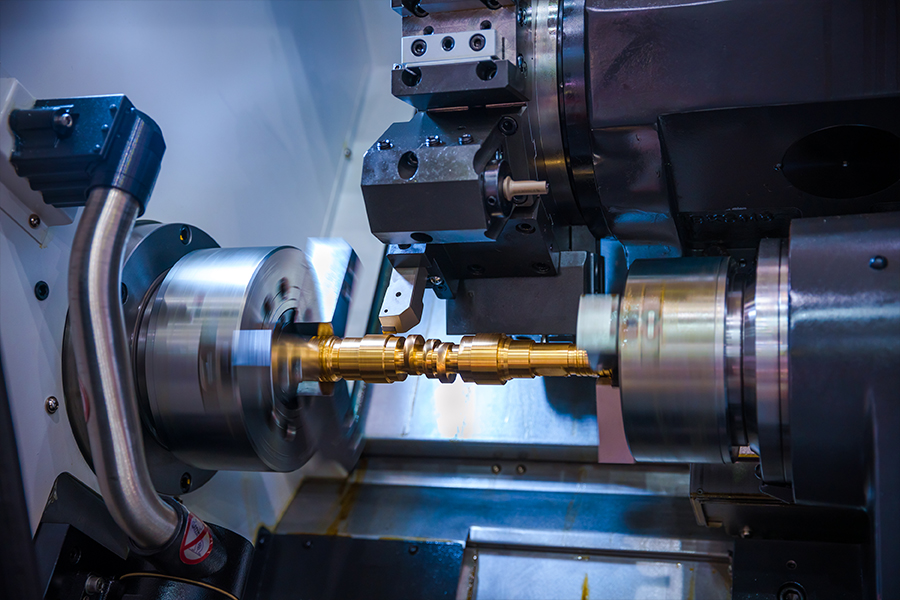

- Turning: there are vertical turning, horizontal turning, new equipment has CNC turning, mainly processing rotating body, say: brass turning parts, aluminum turnining

- Milling: There are vertical milling and horizontal milling. The new equipment includes CNC milling, also known as machining centers, which mainly machine grooves and straight surfaces. Of course, it can also process curved surfaces, using two-axis or three-axis linkage.

- Cutting: The linear surface of the main processing shape, under normal circumstances, the surface roughness of the processing is not as high as that of the milling machine.

- Grinding: There are surface grinding, cylindrical grinding, internal hole grinding, tool grinding, etc., high-precision single-sided processing, and the surface roughness of the workpiece to be processed is particularly high.

- Drilling: hole machining

- Boring: mainly use boring tools or inserts to bore inner holes, process holes with larger diameter and higher precision, and process larger workpiece shapes. There are many processing methods for holes, such as CNC processing, wire cutting and so on.

- Punching: It is mainly processed by punching and forming CNC, which can punch round holes or special-shaped holes.

- Sawing: It is mainly used for cutting processing with a sawing machine, which is often used for cutting sequences.

A machine is assembled from several precision parts. The machine is not complete without these parts.

CNC machining has the following advantages;

- The number of tooling is greatly reduced, and parts with complex shapes do not need complex tooling. If you want to change the shape and size of the part, you only need to modify the part processing program, which is suitable for the development and modification of new products.

- The processing quality is stable, the processing precision is high, and the repeatability is high, which is suitable for the processing requirements of aircraft.

- In the case of multi-variety and small batch production, CNC machining is more efficient, which can reduce the time for production preparation, machine tool adjustment and process inspection, and reduce the cutting time due to the use of the best cutting amount.

- It can process complex profiles that are difficult to process by conventional methods, and even process some difficult-to-observe processing parts.

The disadvantage of CNC machining is that the machine tool is expensive and requires a high level of maintenance personnel.

CNC machining is decoded by a computer, making the machine move and machine the part. The blank is processed into a semi-finished product by a tool