Reaction Injection Molding and Its Applications

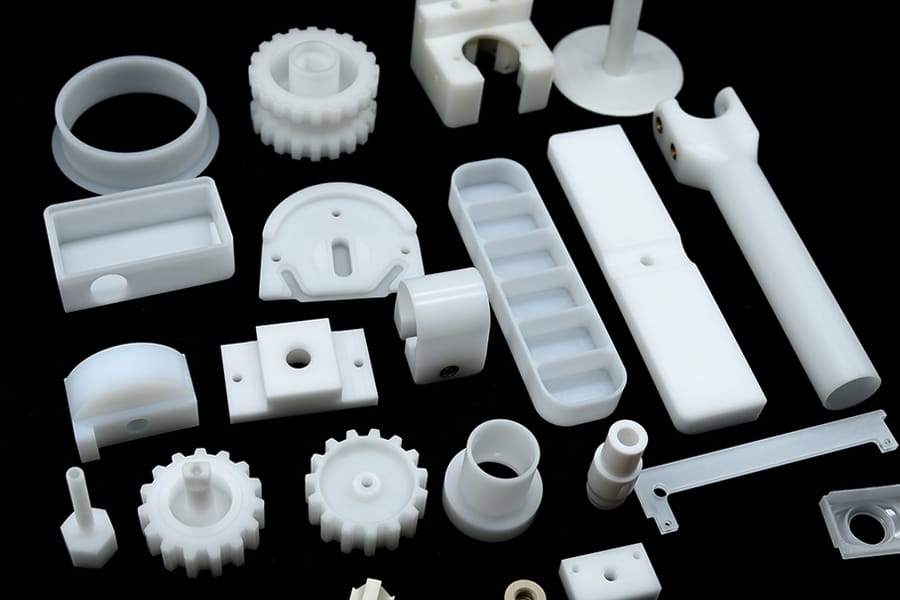

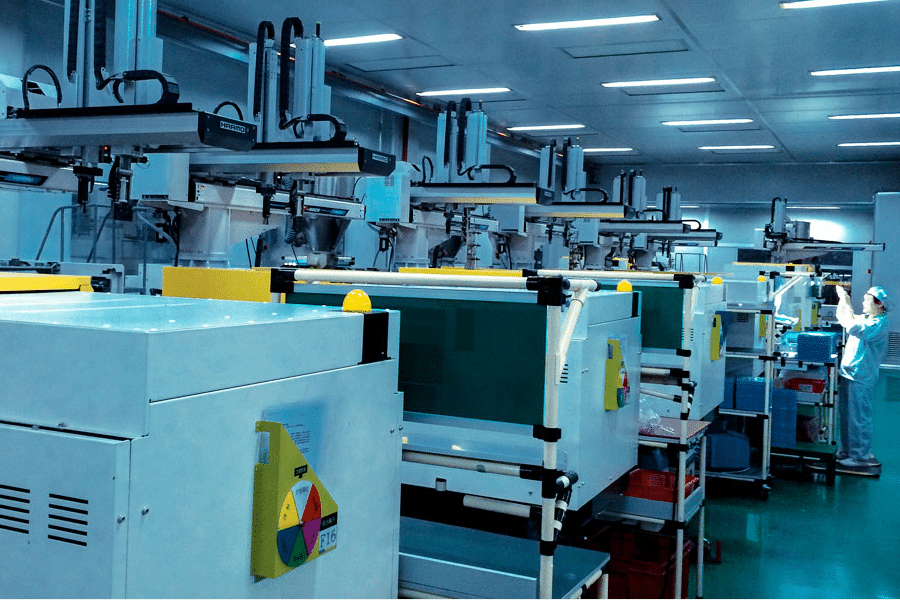

What is Reaction Injection Molding Reaction injection molding (RIM) is a manufacturing process that involves the injection of liquid reactive components into a mold to produce a solid plastic part. It relies on the mixing of two or more reactive components, such as polyurethane, to create a chemical reaction that results in the formation of […]

Reaction Injection Molding and Its Applications Read More »